Railway Operations — II

On this page- Caution Orders, Restrictions, and Blocks

- Unusual Situations & Block Protection

- Banking & Ghat operations

- Traffic Flow (Left or Right)

Caution Orders, Restrictions, and Blocks

Q. Why do trains sometimes slow down on some sections instead of continuing at the same speed throughout?

There are many reasons for a reduction in speed. There may be permanent speed restrictions on the section of track: because of sharp curves or curves with inadequate cant; approaches to crossovers, diamonds, etc.; structures too close to the track; ghat sections; line side tenements or pedestrian traffic; level crossings; old bridges or culverts; inferior track or lighter rails than normally required; unstable trackbed; frequent threat of flooding, etc. The working timetable usually has a detailed list of these restrictions for all sections within a division.

There may also be temporary speed restrictions (also simply temporary restrictions) such as engineering speed restrictions because of construction work or track maintenance, or because of flooding or other track damage, etc., all of which necessitate following the appropriate caution orders or caution notices in force for the section. See below for more on this. Sometimes newly-laid track may not yet have been certified for higher speeds while lower speed traffic is allowed.

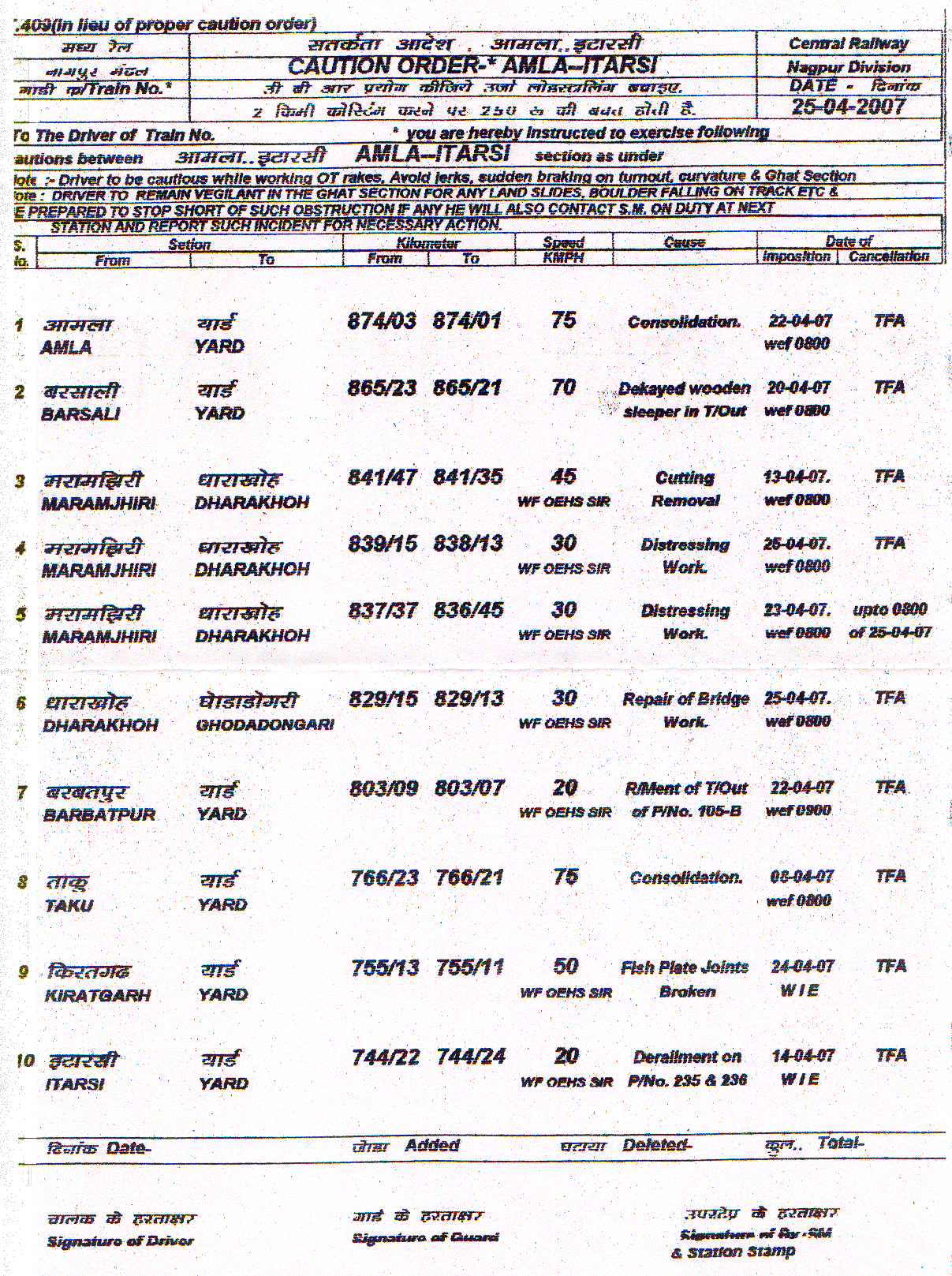

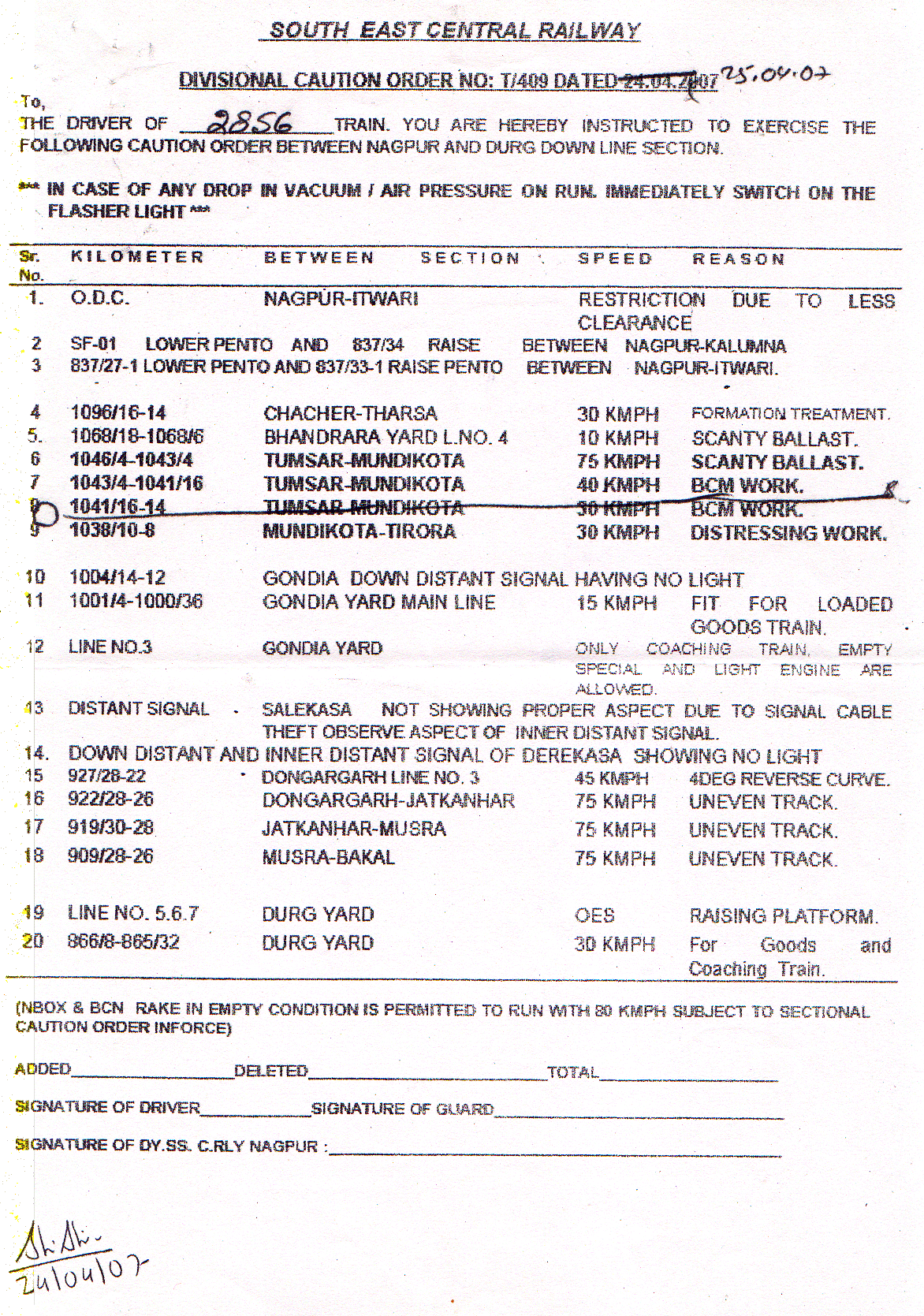

Q. What is a caution order?

A Caution Order (or caution notice) is a written notice issued by a station master (or other official) to the loco pilot and guard of a train, formally advising them of special conditions and restrictions in effect on the section of track that the train is about to enter. The Caution Order may have instructions on speed restrictions and other special procedures to be followed on account of damage to the tracks, flooding, work on the permanent way or on the electrical equipment, accidents (or reminders of spots where accidents recently occurred), work on or damage to OHE equipment, or unusual situations.

A caution order can also be issued to advise the pilot and guard of the presence of manually operated or motor trolleys, tower cars, MOW wagons, or other such maintenance or emergency vehicles that have entered the block section ahead. The caution order usually specifies the location of the affected section of track, the temporary speed limits in effect, the locations of caution indicators and termination indicators, etc.

Some representative examples of caution orders are the following:

- Track doubling in progress - whistle to alert men at work

- Track destressing - 20km/h

- New colour-light signal location

- Level crossing gate - no acknowledgement given; be prepared to stop if gateman does not display hand signal

- Accident spot - 75km/h

- Up distant signal number ... of station ... inoperative due to a cable break; keep a good look-out, whistle while approaching and Proceed

A caution order is generally issued by the station master of a station adjacent to the block section which is affected. In addition, divisional caution orders are also issued by station masters of certain specified stations on the route, known as notice stations.

A caution order is specifically addressed to the driver and guard of a particular train identified on it. Separate caution orders are issued for each train passing through on to the affected section. At many of the larger stations nowadays the caution orders are printed out but at smaller stations, handwritten notes still prevail.

A nil caution order is issued by a notice station to inform the driver and guard of a train that there are no special caution instructions or temporary speed restrictions in effect between that station and the next notice station. A reminder caution order may be issued by a notice station to reiterate caution orders already issued by other stations or authorities.

Q. What are speed restrictions and engineering restrictions?

These are various kinds of speed limits below the normal sanctioned speed limit for the route section in question, imposed in stretches of track where unsafe conditions exist because of track damage, ongoing repair work to track or OHE, accidents, or unusual circumstances in the construction of the permanent way (see above).

A temporary engineering restriction is specifically one that is imposed for a fixed duration on account of ongoing work on the permanent way or OHE equipment; a permanent engineering restriction is one that is in effect indefinitely because of characteristics of the permanent way. Other temporary speed restrictions may be imposed because of flooding, track damage, accidents, etc. A stop dead restriction is one which requires a train to come to a complete halt before obtaining permission to proceed.

For short-duration (1 day or less) temporary speed restrictions, hand signals are used at appropriate points (30m to the rear, and 800m (more in some cases) to the rear) to advise drivers of the location of the restriction. For a short-duration stop-dead restrictions, a red banner flag is placed across the tracks just before the obstruction, and another banner flag is placed beside the tracks (600m BG; 400m for MG/NG) before the location of the affected portion of track. Three detonators are also placed 10m apart, about 1200m (BG; 800m for MG/NG) before the banner. Hand signals are used 30m to the rear of the obstruction and 45m to the rear of the detonators.

For longer temporary speed restrictions (lasting more than a day) a speed indicator is placed 30m to the rear of the affected portion, and a caution indicator 800m (or more in some cases) to the rear. For longer stop-dead restrictions, the speed indicator is replaced by a stop indicator, whereas the caution indicator is placed 1200m to the rear for BG; 800m for MG/NG.

Normally the driver and guard of a train are issued caution orders that provide details of the temporary restrictions. Caution orders are not issued for permanent restrictions of any kind. The caution or stop indicators, banner flags, hand signals, and speed indicators are all dispensed with if the affected portion of track is within station limits and if it can be appropriately isolated by the settings of points and leaving signals protecting it 'on' (at danger).

The caution indicator is also dispensed with if the affected portion of track is protected by an automatic signal less than 1200m (BG; 800m MG/NG) from the obstruction. In this case the detonators and banner flags are placed at 180m and 90m to the rear of the obstruction for a stop-dead restriction.

Q. What are blocks? Line blocks, power blocks, etc.?

A block is a bar on through traffic entering a particular section of track. It may affect only certain kinds of traffic, or may close the tracks to all trains; it may affect one track of a double line or multiple line, or may affect all tracks up and down. A block is used when work of a more involved nature is undertaken and speed restrictions are not suitable because through running on the affected line is not possible.

The simplest is a line block, or traffic block, which blocks a particular track (or tracks) when repair or construction work has to be carried out on the permanent way, points, crossings, interlockings, OHE, signalling equipment, etc. Such blocks are sometimes also called possession blocks (since the permanent-way staff ‘take possession’ of the tracks).

A line block is requested by the engineering official in charge, and granted by the Divisional Railway Manager. The station master of a station adjacent to the affected block section receives a copy of the line block order from the DRM, and he decides when to implement the line block. In busier sections the Section Controller is also involved in deciding when to impose the line block. In some cases, if the traffic disruption is extensive and the block is required for longer than usual, necessitating much rerouting and rescheduling of trains, the block is termed a megablock (or ‘mega block’).

The guard of the last train that is to run through on the section before the line block comes into effect is given the notice from the station master that the line block will come into effect as soon as that train leaves the block section. A caution order is also issued to the driver of this last train, advising him to look out for a stop indicator or signal from the engineering crew. When stopped by the engineering crew, a copy of the line block certificate is handed to them. Once the last train clears the block section, the block instruments are set to line blocked status and remain so until the block is removed.

A power block is a bar on all traffic using electric traction, on account of work on the OHE equipment. In addition to the station masters and Section Controllers, the Traction Power Controller has to coordinate when the electricity supply to the catenary in the affected section is to be shut down. A power and traffic block bars all traffic, not just electric traffic, on the section when work is being done on the OHE. A programmed power block is a power block imposed on a regular schedule as part of the routine maintenance regime for the OHE.

An emergency power block is imposed when accidents or other occurrences cause damage to the OHE or defects are noticed. An emergency power block may also be requested by the driver of an electric loco when it is urgently necessary to perform repairs or inspection of the pantographs and other electrical equipment (especially on the roof of the cab) while the loco is in a block section.

A local block is a block for a siding or loop or other line which is not a main running line. (Similarly, local power block.)

Unusual Situations & Block Protection

(Also see the extracts of IR General Rules on accidents and other extracts from the IR General Rules on train working.)

Q. How are communications or signals failures handled?

In case of signalling equipment or block equipment failure (e.g., power failure, floods), if communications can be established between adjacent stations (by telephone or cellular phones on the public network or control telephones of the railway network, or in the past, by telegraph or bell code), paper line clear tickets may be issued to trains to proceed. Such paper authority is given along with issue of private numbers by station masters to establish proper authorization, authentication, non-repudiation of the action. Paper or verbal authority to proceed (with issue of private numbers) can also be given by section controllers if communications have broken down between adjacent stations.

If there is a total breakdown of communications, the station master of a station can still issue a paper authority to proceed to the first scheduled train departing a station, subject to a restriction to run at or under 15km/h and a requirement to sound the horn or whistle freely to alert any possible oncoming train.

Q. How are trains run when tracks are flooded?

Flooding is very dangerous to the permanent way. The earthworks become unstable, ballast can be washed away, and the forces of the water by its movement, buoyancy, and scouring action can seriously weaken and move the track so that it is no longer stable and secure enough to support the weight of a train reliably.

Hence, great care is taken when flood waters rise and affect a railway track. If the trackbed is known to have been laid in a stable manner (or specially built to withstand floods in a flood-prone area), certain rules of thumb are adopted. If the water level does not cover the ballast and the track can be seen to be undamaged, trains may in general move (with caution) over the affected sections. When the water level rises to cover part or all of the ballast, special operating rules go into effect, which differ based on local conditions.

In some divisions, the rules are that if the water does not cover the rails, it may be piloted across with gangmen walking ahead of it and observing the track as it comes under load; while if the water is above the rails gangmen (and keymen) may have to inspect the entire length of the flooded track first, report it to the gangmate (their superior) and then mate authorises movement with a written certificate.

In flood-prone areas like Mumbai, the tracks are built to withstand a certain amount of flooding. In such cases, the rule is generally that trains can proceed (with caution) on flooded track even if the water is a few inches above the rails, as long as the rails can be seen. E.g., on WR, for water less than 3" above rail level diesel locos are operated at 5km/h, and electric locos at 15km/h. Electric locos can be operated at 8km/h up till 4" of water, while diesel locos (WDM-2) must not be operated if the water level rises above 3".

For each class of locomotive, there is a certain height of water beyond which it absolutely cannot proceed on flooded track as its equipment may be damaged otherwise. For instance, diesel locomotives of the WDM-2 class are not to be used if the water level above the rails is more than 3".

Q. How are trains run in the fog?

Due to restricted visibility in thick fog which pervades northern India in particular during the winter months, trains are known to get delayed and schedules get thrown haywire. Obviously, these delays have their genesis in the fact that the pilots can't see the signals at sufficient distance and have to reduce speeds when approaching signals, so as to be able to take action considering the aspect of the signal as and when it becomes visible.

Earlier, pilots used to check their speeds based on their own judgment and feel. This led to some pilots being exceedingly slow out of caution, while others occasionally overshot signals out of an anxiety to not be seen as ‘dragging their feet’. Northern Railway decided to lay down instructions as to how the pilots should move in fog. These instructions are given below.

Northern Railway: Train operation during fog

Automatic Block System: In automatic signal territory, the maximum speed of a train is restricted in accordance with the signal aspect that the train clears. 60km/h after passing a stop signal at ‘Green’, and 30km/h after passing ‘double yellow’ aspect stop signal. Depending on the severity of fog, the pilot is expected to control the speed of a train and restrict it further if necessary.

Absolute Block System: The maximum speed of a train is restricted to 60km/h in absolute block system territory in dense fog, and depending on the severity of fog, the pilot is expected to control the speed of the train and restrict it further if necessary. Further, special rules are in effect as follows:

- No train awaiting line clear should be advanced beyond the starter signal.

- No shunting is to be carried out on non-isolated lines in a yard after giving line clear to a train.

- All IBH (Intermediate Block Huts) in semaphore signal territories are shut down and converted to single block sections for the duration of the fog.

- Fog signalmen are provided to place detonators 270m in the rear of the first stop signals so as to give the pilots an audible warning of the proximity of the stop signal. (See below; Not necessary when FogPass Devices have been provided)

- Lime markings are made across the tracks at the signal sighting boards.

Although the final decision on the speed rests with the pilot, the upper bounds of 30km/h or 60km/h help them in deciding the appropriate speed, and also allow the operating department staff to make better projections in publishing the revised schedules of trains in foggy weather.

Detonators in foggy weather

Detonators are used in foggy weather or otherwise when visibility is severely impaired, to provide an audible indication to the locomotive crew that the train is approaching a signal. These detonators are flat, disc-shaped metal containers, usually coloured red, which contain an explosive mixture that detonates with the application of pressure (and therefore when the wheels of the locomotive pass over). A detonator is attached to the top of the rail using a metal clasp at the bottom of the detonator. These detonators normally have a shelf life of 7 years, although this can be extended to 10 years with annual inspections. Detonators are provided to the running staff, station masters, signalmen, gatemen and maintenance gangs as part of their standard duty kit.

It is the station master's responsibility to assess whether visibility is impaired badly enough to warrant the use of detonators. At each station, there is a nominated Visibility Test Object (VTO) that is used to gauge visibility. The VTO must be at least 300-350m away for semaphore and two-aspect colour light signals and 180m for MACL signal territory. The VTO may either be a post specially erected for this purpose, with a lamp for the night or it may be the arm (during the day) and backlight (at night) of a semaphore signal; or the light of a fixed colour light signal (day and night). If the VTO is not visible to the on-duty Station Master, then it is necessary to use detonators on all running lines of the station.

Detonators are placed in pairs - 10m apart - at a distance of 270m in the rear of the signal to be protected, which is usually the outermost signal on the approach to a station (in double distant territory, the detonators are placed 270m to the rear of the inner distant signal). Usually, fog signal posts are erected to mark the locations. (11/2004) Recently IR has begun erecting shelters by the side of the track as well, for the benefit of the staff who have to stay there to replace the detonators as each train passes by.

The detonators have a safety radius of about 45m; staff must remain outside this distance from the detonators when they explode, to avoid injury; and locomotive crew also take care not to lean out of the cab on approach to stations when there is a possibility that detonators may be in use.

Deploying the detonators is considered a critical safety-related activity, hence the station master is authorized to call on all available staff for this, even off-duty staff if necessary. During prolonged foggy periods or if there are not enough station staff, the permanent way gangs can also be pressed into service for this.

Detonators are not necessary to be deployed if the locomotives in that section are provided with FogPass devices.

FogPass devices

(12/2019) Recently, IR has begun the use of special pilot-aids for fog operations. These aids are termed Fog Pilot Assistance System for Safety (FogPass) devices and are meant to be used only as an additional aid for the pilot and are not meant to replace standard working rules.

The devices are stand-alone apparatuses and are not inter-linked to any signalling system. They are primarily meant to provide the loco crew an idea of their current position relative to the next physical feature such as a stop signal, level crossing or station.

At the time of commissioning, each device is programmed with a set of routes that a particular loco pilot might serve on. This is done at the zonal/divisional level before hand over to individual pilots. Then before each journey, the crew selects the route for that particular trip and the device utilises GPS to report the distance to the next signal, station etc., using audio-visual indications.

It is important to note that the device does not tell the aspect of the approaching signal. It merely reports the distance so that the crew may be alert to any change in aspect and regulate speed as necessary.

NR and NFR use the devices currently, but other zones are expected to be allocated these over the next couple of years.

Q. When can trains be run without brake vans or without guards?

Normally, all trains are required to have a brake van or guard's van and a guard on board. However, in a few cases the brake van and the services of the guard can be dispensed with, especially in sections where block sections are completely track-circuited, which reduces the possibility of undetected train parting. Brake vans can also be dispensed with on specially designated short sections (typically, less than 30km, as with Northern Railway) even without track circuiting; however in this case a guard must usually accompany the train. The pre-conditions for this are as follows:

- The last vehicle must have a tail lamp or tail board.

- When the train is granted Line Clear, the number of the last vehicle must be recorded and conveyed to the section control and also to the adjoining station.

- The train must stop at every station along the way and the number of the last vehicle must be recorded and conveyed to section control.

- The guard must travel in the leading locomotive, or in the banker if one is provided. Note that a banker is required for operation without a brake van if the grade is steeper than 1 in 200.

- The weather must not be foggy or stormy.

- There should not be any break of communications along the line.

- Single-line working should not be in force if the section is a double line section.

Q. What are the train working procedures in case of accidents, derailments, etc.?

(Naturally, there are well-defined rules on obtaining medical help and emergency services, etc. in the case of accidents, and assisting injured people and preventing further injury or death takes the highest priority. But here we focus only on train working guidelines which come into play for accidents.)

The general principle is to protect the train that has been involved in the accident: this is done by ensuring the block section remains closed to further traffic, and by providing additional temporary signals in the form of flares, detonators, banners or hand signals (lamp/flag), etc. to prevent any train from colliding with the train involved in the accident in case signals have been pulled off at the station at either end, or in case there is a signal failure due to the track circuit not being tripped.

Detonators are placed as follows: one 600m from the train, and three about 1200m from it, 10m apart (on the other gauges the distances are 400m and 800m). If the section is a double line section, the other line is also protected similarly if there is any chance that it might be fouled by the accident or derailment. Passing trains on the other line must be stopped and given information about the accident. The guard is technically responsible for the protection of the train and the adjacent line(s).

The engine crew also help in this, and also ensure that parking brakes are set and the locomotive parked in a safe condition if possible. (If the locomotive is in working condition and can be detached from the train, it may be used to travel ahead to the point where the detonators need to be placed on the track.) The driver also switches on the flasher light of the locomotive (if provided), and sounds the horn in a danger signal. If the loco does not have a flasher light or if the flasher fails, if it is necessary to warn an oncoming train the headlight is flashed on and off.

The flasher on the brake van or guard van (if provided) is also activated to warn trains from the rear. The guard and the engine crew also then attempt to contact the nearest station by telephone or other means, if no passing train could carry the information.

Once information about the accident is received, the signalman or station master of the adjacent station sets the signals to On and the block instruments to ‘Train on Line’, and locks the equipment in that position in order to prevent any other train from being granted permission to enter the section. This is done for both (all) lines on a double (multiple) line section irrespective of the line on which the accident occurred, until it is established that the other line(s) is (are) not fouled.

Normally, even without notification of an accident, if a train is unusually delayed (within 10 minutes of its normal running time), the station master is expected to inform the stations ahead and to the rear and arrange for signals to be left at On and the block section protected. Passing trains on other lines are stopped and informed about the possibility of an accident. If the accident causes the catenary or one or more lines to be damaged, a power block may be applied. Where provided, the emergency siren at the station may be sounded, or other means of notification used to set accident-relief plans in motion.

Assisting locomotives or accident relief trains are given authority to proceed without Line Clear into the block section where the disabled train is, as well as authority to pass a signal at danger (the last stop signal of the station) (unless on double or multiple line sections where the assisting train is moving in the wrong direction on the other track).

A caution order is also issued which advises the driver of the assisting train of the location of the disabled train, and the station to which it should be taken if it is to be moved. If the disabled train is moved, the assisting train is governed by the stop signals of the station to which it is being taken, or, if on the wrong line of a double/multiple line section, it draws up almost to the last stop signal (facing the other way) and waits for the signal to be pulled off or written authority to proceed past the signal at danger to be granted by the station master of the next station.

Q. How are runaway vehicles and out-of-control trains dealt with?

In case of trains passing signals at danger or running through a station out of control, or moving on block sections without authority to proceed, the station master must inform the next station ahead of this occurrence (and on controlled sections must inform traffic control). The station master of that station then sets its departure and reception signals to On, and sets the points to a clear line (likely the main running line if it is clear).

In sections under traffic control, the section controller may set the departure and reception signals, for several stations along the way, to On as a precaution. Signals for adjacent lines on double or multiple sections are also set to On as there is a danger that the runaway vehicles may derail on the block section and foul adjacent lines.

Detonators are provided on the line to alert the pilot if the runaway has a locomotive with a pilot in it. If it is suspected the train is completely out of control and the pilot perhaps disabled, points may be set for sand traps or catch sidings in order to stop the train, but usually not if there are passengers in the train except in extreme circumstances. If the runaway consists of just one or two vehicles, it is usually derailed promptly by using diverting it to a sand trap or catch siding, or even a dead-end siding or loop line, or using derailing blocks. If necessary, a sleeper or other obstruction is placed on the track.

In areas where the exchange of flag signals between the guard or pilot and the station crew or signal staff when a train passes through a station is mandatory, the failure by the guard to display the all-right signal causes the train to be considered a potential runaway and subject to being faced with On signals ahead of it.

Q. How is train parting dealt with?

When IR started transition from the screw coupling to the CBC (centre buffer coupling), it was expected that parting incidents would be reduced. However, the opposite turned out to be true. Regardless of who (the guard or loco-crew) detects train parting, the observing party must inform the situation to the other party, most commonly on the handheld radio provided in both the SLR and loco cab. If the front portion of the train has not yet departed from view, the guard can also use a flag or lamp signal (green, waved strongly up and down) to attempt to indicate to the engine crew that the train has parted. The guard then uses his handbrake and air brake controls to attempt to slow down his portion of the train to a safe halt. If the train is being banked, the banker brings the train to a halt on seeing the guard's signal, and also sounds a danger horn sequence to attract the attention of the loco pilot in front. The air brake system in use in IR, is also fail safe in the sense that in case of any brake component failure (such as excessive pressure drop due to parting), the brakes will automatically be engaged. This was not the case with the, now defunct, vacuum braked stock.

Often the loco pilot will be the first person to notice that the train has parted due a sudden drop in the BP and FP pressure (shown by the air flow indicator and also auto-regression of the master controller) and the reduced load on the locomotive. If lucky, the crew may happen to look out and spot the guard's signal. Under normal circumstances, the loco pilot or his assistant always look back from the cab periodically to visually check that the train is whole (a lamp is provided specially for this purpose on the SLR) and has no obvious problems, especially on curves when all the coaches or wagons are visible. In any case if the crew notices train parting, they inform it to their guard who applies his brakes. The loco pilot doesn't try to stop his portion of the train immediately, to prevent collision between the two parted sections. Any trackside crew that observes this is also instructed to not give the pilot a danger hand signal (red flag) but instead relay this information through physical action or the walkie talkie. If the two portions of the train, after stopping, are close by, and it is possible to couple them together, the train may then proceed normally as a whole train and get inspected at the next station. If it is not possible to couple the portions together (usually due to coupler breakage / draft gear failure), the guard can give the loco pilot written authority to proceed with the front part of the train.

The guard also decides whether the same locomotive should return to assist and move the remaining portion of the train, and gives the loco pilot written instructions to this effect. The loco pilot hands over any tangible authority to proceed that he had been carrying (token, staff, or written authority to proceed) to the guard. The loco pilot takes the partial train to the next station, while the guard stays with the rest of the train after protecting it at the rear with flares, detonators (placed as described above) and possibly using hand signals (flag/lamp) to alert oncoming or passing trains. In bad weather or with poor visibility the front of the train is also protected. Parking brakes are applied where provided, on all the vehicles of the train portion.

In rare instances, an engine failure, loss of power, a fire in a part of the train, or a train stalled on a gradient, may require that a train be deliberately parted by uncoupling the locomotive or a portion of the train. In this case too, the loco pilot hands over his tangible authority to proceed to the guard, gets written permission to proceed from the guard, and then proceeds (with or without a portion of the rake) to the next station.

If the driver notices too late that the train has parted, and reaches the next station and stops there, he does not relinquish any tangible authority to proceed (token, staff, or written authority to proceed) until the rest of the train that is left on the block section is safely brought in by an assisting locomotive and the block section cleared of all the portions of his train.

In the above cases where the driver knows that the train has parted, he must stop at the first station he arrives at and inform the station master that the block section is still obstructed; if a signal cabin is passed the signalman can also be so informed. This allows the block section to be kept free of traffic by leaving block instruments at ‘Train on Line’ and keeping the signals at On.

In the above cases, if the guard has instructed the driver to return with assistance to the remaining portion of the train, the station master grants authority to proceed either on the same line or on an adjacent line for the locomotive to reach the disabled train portion. Block sections remain appropriately closed to traffic when this happens.

If a train passes through a station and is seen (by the station master or other staff exchanging signals with the train) to have parted (i.e., does not have the Last Vehicle sign or lamp on the last coach or wagon), the block instruments for the section to the rear are kept at ‘Train on Line’ and the station to the rear is informed of the parting of the train; signals remain on so that the block section cannot be entered by any other train. In addition, the station ahead is informed of the train parting so that the signals there can be set to On to stop the train. A cabin man or the pilot of a train going in the other direction may also notice a train has parted — the procedure is similar in such cases, with the nearest stations being informed and the block section closed off to other traffic.

Q. What happens when the Alarm Chain (Emergency Chain) is pulled in a coach? (ACP, Alarm Chain Pulling)

The alarm chain in a passenger coach is designed to create a break in the continuity of the brake pipes (earlier vacuum, now air brakes), immediately resulting in a loss of brake pressure and thereby causing the train brakes to be applied. With vacuum brakes, a clappet valve was provided that was released by the pulling of the alarm chain, and with air brakes, there is a similar passenger emergency valve that can vent the brake pipe to the atmosphere. See the page on IR brake systems.

At the locomotive, in addition to a warning lamp or buzzer being sounded, in most locos the master controller undergoes auto-regression, with the notches falling to zero rapidly as the locomotive's motive power is switched off. The guard may also notice the loss of brake pressure (although he may not know it is due to the pulling of the alarm chain) and is expected to apply his brakes as well immediately. It is possible for a driver to override the alarm chain pull in a few circumstances, and this is in fact done in a few cases where it is known that miscreants resort to pulling the emergency chain solely to get the train to stop at a point convenient for themselves (but note that such an act by the driver or guard of deliberately ignoring an indication of alarm chain pulling is a serious offence).

Locos have also been fitted with emergency flashers on the roof of the cab, and these flashers are also activated when the brake pipe pressure is lost for any reason other than the driver's application of the brake valve (A9) (emergency application still turns the flasher on). This alerts drivers of oncoming trains of the possibility of a derailed or parted rake which may foul other tracks, since the brake pressure may have been lost for those reasons as well, and at the locomotive it is not possible to tell whether the loss of brake pressure is due to the pulling of the alarm chain.

ACP also causes a small flap to be released near the emergency brake valve (usually mounted near one end of the coach) which does not retract to its normal position even when the chain is released. This allows the driver or guard to find out in which coach the ACP actually occurred. When the coach is isolated, the lever needs to be manually reset. Until this is done, the lamp and buzzer in the locomotive cab are continuously activated. A circuit breaker controls the lamp and alarm bell in the locomotive cab; in cases where defective equipment causes the lamp and bell to go off, the driver can disable them by placing the MCB in the ‘off’ position; despite the obvious safety hazards, sometimes this is resorted to by drivers when driving trains through sections where spurious ACP incidents are very common.

Q. What are catch and slip sidings? How are runaway trains managed?

Catch sidings are sidings provided to divert runaway trains off the main line on approach to a station, or on steep downward slopes. Points are normally set to route all trains to the siding, which may end in a sand trap to slow down and halt any train that is moving too fast and out of control. This prevents runaways from entering station or yard limits, or from hurtling down a slope and derailing.

A train that has to proceed on the main line must come to a halt before the catch siding (usually a signal is provided for this), and wait to get authorization to proceed. In some cases, this happens when the driver sounds the horn or whistle to let the signalman or station crew know the train is waiting for the authorization to proceed. In some cases, especially in remote areas, the loco crew is provided with a key by the signal cabin in advance; this key unlocks the points to allow the train to proceed on the main line.

In a few cases, there are also automatic points that have sensors that set the points after detecting that the train has approached and waited for a prescribed period of time (usually 90 seconds). In less busy sections, station crew or pointsmen may also arrive to manually set the points using a lever at the location, rather than operating them remotely.

Slip sidings are similar, but they are located on main lines in the direction away from a station or yard. Again, the points are normally set to divert all trains away from the main line, and a train must halt until the points are set and the signal (if provided) pulled off before proceeding. Slip sidings are often provided when there is a downward slope (greater than 1 in 26 or so) away from the station or yard, as then there is a risk of stabled rakes rolling out of the station or yard limits if the brakes fail.

Slip sidings are also provided on single line sections at cross-over points to protect trains that are waiting for a cross-over, from collisions if a train coming in the opposite direction fails to stop in time and overshoots the cross-over points. Slip sidings are also used when a double line ends to become a single line.

Shunting operations in yards are also normally carried out with the points set normally to lead away from the main line, except for very rare occasions where shunting activity must be carried out on the main line. For any train starting from the station (either with rake having been marshalled there or with coaches or wagons having been attached or detached at that station), where vacuum or air continuity was lost and brake power has to be rebuilt, the points are set for the main line only when the pilot signals (using the horn or whistle) that brake power has been regained fully.

Banking & Ghat Operations

Q. What are bankers? Why are bankers used?

A banker is a locomotive that assists in hauling a train up a steep gradient. A banker is attached to the rear of the train and pushes the train from the rear while the normal locomotive of the train pulls it as usual from the front.

Bankers are used for two reasons. One is that, of course, the leading loco may need assistance on a steep gradient. However, a more important reason to have a banker at the rear when ascending a grade is to protect the train from a possibility of coupling failure and consequent parting which would cause a portion of the train to hurtle backwards because of the gradient (guard's brakes being generally inadequate for such a situation). When descending a grade, bankers may be attached at the front to provide extra brake power (or sometimes just to allow the locos to be returned to their shed after having banked trains up the grade earlier, without taking up a separate slot on the timetable).

On an incline, when the train is being pulled up, the couplers come under a lot of strain. Normally, on level track, the couplers only have to sustain the forces corresponding to the static and rolling friction of the wagons or coaches. But when being pulled up, a component of the wagons' or coaches' weight also forms a part of the load on the couplers (the proportion of the weight arising from the sine of the angle of the gradient). Hence, there is a much higher probability of coupler failure when going up an incline. Finally, the additional locomotives help contribute extra brake power for the rake on the slope.

Often two, three, or even more banking engines may be provided on particularly steep grades and for heavy freight loads. It is common to see 3 rear bankers for passenger trains with 21+ coaches. On the Igatpuri-Kasara section even descending trains get two or three front bankers. Sometimes, however, bankers are attached to trains simply because there are available locos that need to be returned to one shed or the other, and using them as bankers is a way to move them rather than sending them light and reducing track utilization. The working timetable for a division specifies the local rules in effect for how many and what kinds of locos to use as bankers for different kinds of trains and loads.

The safety requirements for train operation set forth by the Commissioner of Rail Safety forbid operating passenger trains on steep gradients without bankers. Goods trains are sometimes operated on such sections without bankers if loads are light. EMUs are sometimes moved between Pune and Mumbai for maintenance and no bankers are used in such cases on the ghat sections as they are not carrying passengers.

The specific rules for what inclines necessitate bankers may vary from one zonal railway to another. In addition, bankers must be used for gentler inclines if there are special circumstances such as operation without brake vans.

See the section on couplers for some information on the limitations of the ordinary screw coupler used most commonly on BG passenger stock. The limits on the tensile force the screw coupler can handle necessitate the use of bankers for most Mail or Express trains these days even on fairly gentle gradients of 1 in 60 or so, since the rakes have been getting longer (and therefore heavier) in recent years. Hence the Nagpur-Itarsi ghat section requires bankers for all passenger trains with 18 or more coaches. However, trains hauled by WAP-7 locos (their extra horsepower contributing) generally do not need bankers unless local weather conditions demand (heavy rain causing wheel slips and loss of adhesion etc.) Trains hauled by WAP-4 or other lesser power locomotives always require a banker.

Many longer trains are run through on the ghat section for fear of overstressing the couplers if a stop is made and the train has to start on the incline. With CBC couplers, the allowable tensile loads are far higher. Goods trains with CBC couplers often don't need bankers on slight to moderate inclines for train parting reasons, but may require bankers to assist the leading loco.

Often, brake vans were removed from the rake before a banker was attached at the rear, because 4-wheeled brake vans were light and did not share the same mass/inertia characteristics of the freight wagons, causing them to be jolted around excessively and very often jumped the rails due to the buffing action between the wagons and the banker locos. Newer, longer 8-wheeled brake vans in use today don’t have this issue and thus are kept in the formation, unless required by local operating procedures.

In addition to the use of bankers, ghat sections often have special rules of operation. Mandatory brake halts are provided for steeper grades so that a brake power check can be done before the train proceeds on to the grade. Stopping at the top of a grade before descending also ensures the train is under control before proceeding.

In steam days it was often common, for the steeper grades, to inspect all the brake cylinders of the rake at the mandatory brake halt, with defective ones being replaced immediately. There are also timed signals provided in some places (see below); the train must stop at the signal for a specified time before it goes off and the points switch away from the catch siding, ensuring that only trains able to come to a halt there can proceed. ‘Auto Emergency Brakes’ are provided for locos intended for use on several ghat sections. These apply the brakes automatically if the speed exceeds a certain threshold.

Q. How do the drivers in the leading loco(s) and the banker(s) communicate?

These days, it is more common for crew to be issued walkie-talkies, so communication is a bit less of a problem, but without them, coordinating the banking efforts with the leading loco always called for great skill and ingenuity. The drivers made use of horn signals, brakes, and also closely observed the load on the locomotives (by monitoring the traction motor currents, engine rpm, etc.). With all this, the drivers ensure that the leading loco does not handle too big a load (putting the couplers under strain), nor do the bankers handle too much of the load (working against the leading loco).

In steam days it was even harder, as there was no convenient gauge corresponding to the motor current or other meters in modern locos that allow judging the load. Then, all communication was through the whistles, monitoring the vacuum in the brake pipe, and monitoring the steam intake and ‘listening’ to the loco!

Q. Are there any special requirements for locos to work ghat sections?

Many locos can be used as bankers on ghat sections. Usually, goods locos are used for banking duties, although this is not a rigid rule. The leading loco on a ghat section can in general be any loco provided it has suitable braking systems, etc.

There are some ghat special powers — locomotives that are specially modified for duties on steep gradients. These are usually equipped with an ‘Auto-Emergency’ (‘AE’ or ‘AEB’) brake system, which is an electronically controlled system which monitors the speed of the loco and applies the brakes automatically if it exceeds 25km/h (or other speed limit appropriate for the section).

These powers are especially used on steep gradients where catch sidings may not be provided (e.g., on the Braganza Ghat between Castle Rock and Kulem; in contrast, CR's Lonavala-Karjat section section has catch sidings and systems like AEB are not used). The AEB system is normally kept switched off in normal sections, and switched on only in the ghat section; the keys for these are kept with the station masters so that the drivers do not have the ability to override the system. Gooty and Hubballi are the only sheds currently where locos with AEB are regularly homed. In the past (2003), only Gooty homed such locos and was thus the exclusive supplier of locomotives on the Braganza Ghat. (2006) There were reports of some 14xxx series locomotives homed at Krishnarajapuram with ‘AEB (30km/h) restriction’ markings on them, but their current status is not known.

Prior to 2006, there were many WDM-2/2A/2B locos with AEB but they were phased out, and the locos with AEB are now WDM-3A, WDG-3A, WDG-4 and WDG-4D units.

A further safety feature in the Castle Rock - Kulem section is the running of trains in the so-called corridor system, where multiple goods trains are run in the same direction on the ghat section at times when passenger trains are not run, to maximize goods throughput while not endangering passenger trains in case of runaways.

There are many mandatory brake halts provided on steep sections. At these locations, the train must come to a complete halt before proceeding. Delayed signals are usually provided, which automatically clear after a track circuit with a timer detects that the train has stopped for the requisite amount of time. Usually, there are automatic points provided at these locations as well; if the train does not stop for the required duration the points will not be set for the main line and the train will be diverted to a catch siding or trap. Sometimes the brake halt is operated manually: a staff person is stationed at the halt and works the points and pulls of the signal only after the train has come to a halt, and the driver has signed in a register maintained for the purpose.

The drivers for trains negotiating steep ghat sections also have special training in driving on those sections.

Traffic Flow (Left or Right)

Q. Which side does traffic run on the tracks in India?

Like road traffic, railway traffic is also on the left as a rule. The rule generally applies to all double-line sections, and a train moves on the right side tracks only in exceptional situations. Of course, it does not make any difference for single-line operations, and bidirectional movement is allowed on both tracks in the case of twin single-line sections.

In the case of some ghat sections and others where there are three tracks, the central one is used for traffic in either direction. In a few cases right-hand-side running (also sometimes known as ‘American style’) is adopted. This was the case on the MG sections between Tambaram and Chengalpattu and surrounding areas. The reason for that was that the MG locos (YAM-1, etc., YDM-4 (short hood leading), steam locos YP and YG) and the MG EMUs all had right-hand-side seats for the drivers. This made right-side running more convenient since the signals are located by the side of the permanent way and not between the two tracks.

BG electric locos all have the pilot’s seat on the left. Most BG running is on the left, and almost all BG signals are on the left side of the track. BG steam locos had the driver's seat on the right, as does the WDM-2 and its upgraded variants (from the American designs). In all of these the drivers depended on the assistants calling out the signal aspects, especially with the long hood leading.

Perhaps to fix this situation, the WDG-3A ('baldie' and short hood) and WDM-3A ('baldie' only) switched to a left-side seat for the pilot. However, curiously, the newer WDM-3A locos have been given a right-hand-side seat for the driver. The newer WDP 4, WDG-4, WDG-4G series and the WAP 4, 5, 7 locos have controls on the left hand side.

One curious oddity today is the Dhanbad-Sindri section where between Pradhankhanta Jn. to Sindri traffic is on the right. The section between Madurai Jn. and Vadipatti is another where the traffic flows on the right.

Please refer to Part 1 (Train services, train crew, working timetable, loco changes etc) and Part 3 (Scheduling, rake sharing, communications etc;) for more on operations.