Exploring India's Marshalling Yards

by Ravindra Bhalerao, 2008

It is a shame that the average rail enthusiast who finds his heart beating faster with a growing sense of excitement at the sight of the Grand Trunk Express pulling into a station, is only mildly stirred as he watches a freight train moving endlessly as it draws out of a yard. But it is not a mere lack of interest that characterizes this phenomenon. There is something about the freight train that seems to be positively repelling. It conjures up pictures of labourers carrying bags of cement, lines of lorries queued up beside a goods shed, and fierce looking merchants crowding around goods clerks eager to book their consignments. It is a dull and uninteresting picture of the world of trade, commerce and labour.

Dale Carnegie once said that, "if you are interested in it now, it is because you have learned a new and strange fact about it -- the entirely new is not interesting; the entirely old has no attractiveness for us. We want to be told something new about the old." If we are to profit by this piece of advice we must turn back to the past and take a look at what goods train working was like in earlier times. And we must strive to learn something new that we didn't know before, hoping, as we do so, to discover something of value that will help to rekindle the spark of enthusiasm for a subject long regarded as dull and tiresome. Let us then turn our attention from the lorries waiting at the goods shed and devote ourselves to gain an understanding of the types of goods traffic that existed sometime during the pre-independence era. The railway enthusiast is sure to find something of interest here; besides, this preliminary exercise will pave the way for a clearer understanding of marshalling yards which we take up at a later stage.

Goods Trains in the First Half of the Twentieth Century

The goods train of today has a feature that brings it one step closer in similarity to a passenger carrying train. The railways have discovered that it is more remunerative to transport goods in block loads, or block rakes as they are known. The system of splitting up a train into two or more parts in a goods yard and dispatching them to different destinations still persists but only in a limited way. Quite a few of our marshalling yards have actually closed down; some have even been dismantled. Those that remain see very little activity as compared to the past, and are a wistful reminder of a vast and elaborate set-up that once served the object of allowing different kinds of goods services to be operated to meet the needs of various types of traffic.

Classically, there were four broad categories of goods trains in the first half of the twentieth century:

(A) Departmental Trains which are trains meant for the carriage of railway material such as ballast, sleepers, rails, or even coal.

(B) Through Goods Trains: A Through train is a term used to describe a goods train which runs from one goods yard to another without having to attach or detach wagons, or load and unload parcels at stations en route.

Consider for example a goods train originating at Bombay, with 25 wagons bound for Katni, the remaining 25 booked for Jhansi. Can this be termed a through train? The route for both destinations is the same up to Itarsi, so the train is a through train from Bombay to Itarsi. Once it reaches Itarsi, the two halves are uncoupled and shunted onto separate tracks in the marshalling yard. Katni bound wagons have to wait till other wagons bound for the same destination materialize. When a full train load (about 50 -60 wagons) has accumulated, it is dispatched as a through train from Itarsi to Katni, and a similar thing can be said of the other half bound for Jhansi.

(C) Section Trains: Through trains are generally formed for the conveyance of goods in bulk over varying distances, an example being a train on its way to a power plant carrying wagons laden with coal from a colliery. However it would be nonsense to imagine that goods of each class will materialize at the loading point in such quantities as to make up a train load at a time. A merchant , for example, may have a consignment of apple crates numerous enough to fill up two wagons which have to be delivered to a point a few stations down the line. To handle goods items of this kind a special kind of service was run known as a Section train, also known as a Shunting train.

A section train runs over short distances (usually from one marshalling yard to the next, e.g., Nagpur to Itarsi), and consists of a mixture of wagons bound for different wayside stations along the route. The main feature of these trains is the geographical, or station-wise order in which the wagons are marshalled. Thus, if A, B, and C refer to successive stations along the route, the first two wagons next to the engine will be for station A, the next one for B, the following three wagons for C, and so on. This arrangement is essential so that when the train halts at a place, it becomes a simple matter for the engine to extract the wagons for that station before depositing them at the goods shed for unloading.

Not all wagons deposited at the goods shed will be loaded ones - some of them could be empties too. For example, when a station master finds that a consignment large enough to form one or more wagon loads has been booked at his goods shed, he informs the Control office saying that he needs so many empty wagons for loading. Control which receives several such requisitions for empties, consolidates the data and passes on the information to the yard which forms the train giving them instructions to attach the appropriate number of empties to the train for distributing at various points.

How does the train crew know how many wagons should be deposited at a station along the way? The answer lies in a document in possession with the guard known as a Wagon Way Bill. A way bill is prepared by the yard where the train originates and contains details of each wagon such as the starting point and destination, wagon number, whether loaded or empty, name of the owning railway and so on. When the train arrives at a station, the station master scrutinizes the way-bill and proceeds to prepare a shunting order for the crew which gives details of the various shunting moves the engine needs to make to deposit the wagons at the goods shed. Shunting may also involve picking up one or more wagons already lying at the goods siding. When the process is finally accomplished, the station master makes amendments to the way-bill, deleting entries for wagons that were detached and adding on particulars of those that were picked up from the goods shed.

As the section train moves along it deposits its load at stations along the way, simultaneously picking up wagons - some loaded, others empty. The progress it makes often amounts to a leisurely exercise for a section train is given the lowest priority when deciding on crossings and precedences. Halts at intermediate stations are unpredictable, sometimes lasting as long as 10 hours, so it is not uncommon to find an exasperated driver and guard nearing the end of their duty shift while the train lies stalled at a station. A phone call made to Control will bring relief in the form of a new set of crew who have arrived by an express; the previous staff now thankfully hand over charge and proceed to return to the nearest station that has a running room facility. This method of working means that the speed of a section train is necessarily low : the average speed can work out to be as low as 5 - 8 kmph, with a run of a few hundred kilometers taking as long as 4 - 5 days.

By the time a section train reaches its destination yard, the original set of wagons it started out with have been left behind at intermediate stations. The train now consists of a different set of wagons picked up along the way, with loads bound for stations distributed randomly across the length of the train. It is now left to the marshalling yard to rearrange these wagons (together with those arriving on other section trains) to form appropriate groups, each group consisting of loads for a certain route arranged in station-wise order.

(D) Road Van Trains: These trains, also known as Smalls Quick Transit or SQT trains, were goods services specially designed for the clearance of goods items which are not large enough to make up a full wagon load. Items of this kind are generally termed as 'smalls' ; they include such consignments as a crate of tea leaves, tins of sweet oil, a cupboard, a few sacks of foodgrain, or a box packed with stationery.

A road van train is made up of around 45 wagons one of which is a 'rest van' carrying an extra set of crew (driver, firemen and guard), so that while one crew operates the train the other can take rest. The rest van also carries a van goods clerk together with a set of hamals. No detaching of wagons is involved at wayside stations: the train is admitted to a platform where loading and unloading of parcels is done by the hamals while the van goods clerk has the job of supervising operations and taking care of the commercial side of the work.

All this is straightforward enough, but the interesting part comes when we pause to think that a van train may carry packets for scores of destinations. If you survey the goods shed at the loading point where the train originates, you will find the platform strewn with thousands of parcels, neatly arranged in heaps according to destination. Clearly, some kind of a system is needed for loading these parcels onto the train so as to prevent unnecessary confusion and wastage of time in handling on the way.

A loading foreman at the starting point sits at his desk on the platform and studies the summary of goods which shows the number of packets for each station as well as their weight and other details. If the foreman finds that there are enough parcels for a certain station to form a full wagon load, he instructs his hamals to pack these items into a wagon and seal it to the point of destination. Such a van, known as a Through Sealed Van (or TSV), will have to be opened only at the destination station for unloading, no further operations being required on the contents en route.

The foreman does his best to prepare as many TSVs as he can. When no further TSVs can be formed, his next concern is to see if parcels for any two stations along the line can be combined to form a wagon load. A van of this sort need be opened at only two unloading points, and is called a Two Station Sealed Van or TSSV, whilst sundry packets to be delivered along the line are packed into what is known as a Collecting Road Van, or CRV.

The main object, of course, of preparing such vans is to utilize each wagon to its full capacity and minimize the amount of handling on the way, but no matter how intelligently the work is done, it is almost certain that a group of consignments will be left over which doesn't fit into any of the categories above. Packets of this kind are generally those meant for far flung places, or perhaps stations that lie on a branch line beyond the next marshalling yard. As such miscellaneous items cannot be left out, they are dispatched on the same train in one or more wagons labeled as 'Junction Sealed Vans' or JSVs, which are to be dealt with further at the next main station.

Once the train is on the move the van goods clerk, though seated in his rest van, has a full time job to do. Packets collected at intermediate stations are loaded by the hamals into empty wagons that have been attached to the train at the starting point. As more and more consignments picked up from wayside stations begin to materialize, these packets together with those already being carried in Collecting Road Vans stand a much better chance of being sorted out into more convenient groups. The van goods clerk must therefore closely study the goods summaries and plan out things while on the run so that when the train halts at a station, he unloads these packages onto the platform, sorts them out according to his plan, and reloads them so as to form as many TSVs and TSSVs as he can. Repacking work of this kind at wayside stations was a regular feature when Road Van trains were in operation.

When a road van train pulls into a marshalling yard, Junction Sealed Vans for that station (also loosely referred to as Repacking wagons) are uncoupled and shunted away to a spacious platform with tracks on either side known as a 'Repacking Shed'. The work done at a repacking shed is quite similar to what was done at the goods shed at the starting point. Junction Sealed Vans coming from various directions are lined up at the platform, parcels are unloaded and a foreman moves around studying the goods summaries to decide how best to 'repack' the wagons. The object, as before, is to reload the consignments systematically, forming Through Sealed Vans, Two Station Sealed Vans, and other kinds of vans that will be ultimately dispatched by various van trains leaving the yard.

The Need for Marshalling Yards

An American writer once said that "marshalling yards are the heart that pumps the flow of commerce along the tracks." In saying this the writer has made a comparison which could scarcely be improved upon, but for those who are new to the subject this may sound like one of those pompous utterances that are often made to rescue from obscurity something that is insignificant and raise it to a place of supreme importance.

Let us refrain from any further arguments. It is easier to understand what a subject is all about after you have studied it in full than by engaging in a debate over what it is all about and what it is not. Nevertheless, for those who are technically minded and who feel a certain pleasure in having everything clearly spelt out and defined, here's the definition:

A marshalling yard is a place where goods trains and other loads (such as wagons coming in from a nearby goods shed) are received, sorted out according to a plan, and new trains formed and dispatched onwards.

Marshalling yards were indispensable in earlier times, and were built at all strategic junctions and intersections. Their need arose due to an inherent feature of goods transportation by rail, namely, that goods arriving at a loading point don't always materialize in such quantities as to make up a full train load at a time, and even when a train-load of traffic is offered, the material may not all be booked for the same destination.

Now that the reader is familiar with the different types of goods trains that were in operation earlier, it is easy to see why these trains had to be split up and sorted in yards. Road Van trains (carrying smalls traffic) entering a yard needed to be broken up so that Junction Sealed Vans could be hustled off to the repacking shed. And at the end of the repacking process, these wagons had to be attached to various Van trains leaving the yard. Secondly, section trains (carrying wagons loads of traffic) needed extensive shunting to rearrange wagons in geographical order. Even those very convenient, long-distance through trains (carrying block loads of traffic) would often need to be split up and rearranged to allow different portions to be dispatched in different directions.

To digress a bit, it will be helpful if the reader is clear at this stage about what is meant by a block load. A train loaded entirely with coal from a colliery headed towards a power plant is an example of a block load. A block load is essentially a train load of wagons which move from one point to another without having to detach or attach wagons en route. Earlier, we had seen an example of a train originating at Bombay, with 25 wagons for Katni and 25 wagons bound for Jhansi. This train will travel undisturbed upto Itarsi, as we saw before, so this constitutes a block load for Itarsi.

The model railway enthusiast who owns an ambitious layout offering both passenger and freight services can easily rearrange and marshal his trains by lifting his rolling stock bodily from the track. On the real railways, an arrangement that is speedier and more convenient is called for.

Kinds of Yards

Marshalling yards, depending on the kind of shunting they employ, may be classified into the following three types :

- Flat yards

- Gravity yards, and

- Hump yards

Below in Figure 1 we see an example of a flat yard which shows the three basic ingredients of every yard, namely, the reception yard, the classification yard (also known as the sorting yard), and the departure yard. On arrival, a goods train is received in the reception yard and the engine is sent to the loco shed (not shown). Adjacent to the reception yard, we see the classification yard, where each line is reserved for wagons going in a particular direction. The subject of nomination of lines is dealt with in greater detail at a later stage; for the present it is enough for us to know that the process of sorting consists of breaking up a train and depositing wagons in the sorting yard on lines nominated for various destinations.

To sort a train that has arrived a shunting engine attaches to the train from the left end in the figure and draws it out of the reception yard onto the shunting neck AB. The first four wagons remote from the engine have to be deposited on line No.3, let us suppose, so the pointsman on duty uncouples these wagons and signals to the driver. The engine pushes the train towards the sorting yard after which it draws back into the shunting neck. The 'first cut' of wagons at the front which have been set rolling move into the nominated line where they are brought to rest by brake porters who run alongside the wagons pinning down the handbrakes. How do the men operating the sorting yard points know which line a 'cut' is to be sent to? There are various methods employed for this, one of which we shall describe shortly.

A second push-pull operation will deposit another set of wagons (i.e., the second cut) on the appropriate line in the sorting yard. The push-pull method is employed in flat yards where the whole layout is built on level ground. This is the simplest arrangement, but it also turns out to be more costly to operate as the shunting engine continually moves up and down while sorting is in progress. Flat yards have been traditionally used on the metre gauge in Indian Railways; they may also be found on the broad gauge at places where goods traffic is light. Though simple in construction, they are incredibly slow in operation, with an average goods train with about 50 cuts taking as long as 2 - 3 hours to sort out.

Another kind of yard is the gravity yard where a gentle slope on the shunting neck falling towards the sorting lines assists wagon cuts in rolling down by themselves without engine assistance. Gravity yards are considered ideal, but topographical features often do not favour such an arrangement.

The best compromise is the hump yard. This is illustrated in Fig. 2 below which shows reception lines joining up into a single line which slowly begins to ascend an artificially made 'hump' or hill. When the track has risen to a height of around 8 - 10 feet it levels off and begins to descend towards the sorting yard. The descent grade could be anywhere from 1 in 25 to 1 in 35 up to the first point of divergence which is known as the King point. Beyond this is a gentler grade (1 in 80 to 1 in 200) which eases off into a still gentler grade of 1 in 400 to 1 in 600 where the fans of lines commence. The entire sorting yard is thus laid on a downward grade.

The sorting yard points were operated from a set of ground frames, although in later days these came to be replaced by a single elevated cabin. It will be seen that the yard above doesn't have a shunting neck as in the flat yard shown earlier. The shunting neck is not needed in this case as the reception and sorting yards are in continuation and a train can be directly pushed from the reception area onto the hump for sorting work.

The process of sorting a train in a hump yard in earlier days was as follows:

The Assistant Yard Master (AYM) who sits in an elevated cabin with windows all around prepares a 'cut list' for the train showing the number of wagons in each successive cut and the line on which the cut is to be sent. A copy of the cut-list is given to the shunting master operating from the same cabin, who uses the document to issue orders on loudspeakers (some of them of the talk-back type) placed at strategic locations within the yard.

Each shunting master has under his charge a shunting engine and a set of pointsmen. Under directions from the shunting master, a shunting engine attaches itself to the rear of the train and begins to push it out of the reception area towards the hump, movements taking place at normal shunting speed.

The shunting master has a full view of what is taking place from his look-out cabin and when he finds that the leading wagon is nearing the summit of the hump, he issues his first order on the microphone: "Chaar gaadi kato ... saat line par dalo!" (uncouple the first four wagons and send them rolling down line No. 7).

A pointsman stationed on the hump signals to the driver to slow down, the signal being picked up by a relay pointsman standing midway down the line who transmits the message to the driver. When the train has slowed down to a snail's pace (about 1 kmph) the hump pointsman steps between the wagons crouching under the buffers and disengages the coupling link, while another pointsman a little way off pins down the hand-brakes partially so that the wagon cut doesn't hurtle down the incline at dangerous speed. In the mean time, those at the ground frames (or cabin as the case may be) have set the points on hearing the announcement, while the brake porter will have moved to the appropriate line in the sorting yard in readiness for the wagon-cut as it comes gently rolling along.

Despite the application of handbrakes by brakeporters stationed at the appropriate place, wagons hurtling into a sorting yard would often bang against those lying further down the line. Loose shunting of this kind, when carried out roughly, often led to troubles such as loads on open wagons shifting out of place, or hot axles occurring at a later stage. Brake porters often carried with them a mechanical contrivance known as a skid used to further slow down a rolling wagon. The action of the device is simple : when a wagon wheel comes across a skid clipped onto the track, it rides on top of it and drags it along, the skid preventing any further rotation of the wheel.

Humpyard sorting can be quite a slow process, a train with 40-50 cuts taking about half to one hour's time to sort. But it is still quicker and requires less engine movement when compared to a flat yard. The humpyard design is thus ideally suited for places which deal with a substantial number of wagons each day.

The Marshalling Yard Layout

There are two ways in which a marshalling yard layout can be planned. In one arrangement, known as a multiple yard, there are two sets of reception, classification and departure yards, one for the Up direction and the other for the Down direction, lying side by side. With the exception of the New Itarsi and New Katni yards and a few other places, Indian Railways have traditionally followed this design on its layouts.

From 1930 onwards, most European countries abandoned the idea of multiple yards and changed over to the idea of single yards. A single yard, as its name indicates, has just one set of reception, classification and departure yards serving both up and down directions. A yard of this type requires less space to construct, and saves not only on capital cost but also on staff. It is also a lot more easy to understand.

Single Yards

To see how a yard works consider Fig. 3 below. This is a single (or unitary) yard with reception, sorting and departure yards in series, having connections as shown. An up train arriving from the left enters the reception area where the engine detaches and returns to the locoshed using connection B. For a train arriving from the right, entry will be via the dotted line, the engine leaving for the shed using crossover A.

To the right side of the sorting yard we see a shunting neck which allows wagons to be drawn out of the sorting yard and placed at 'local installations' such as the repacking shed, sick yard and weigh bridge. The shunting neck is usually a short piece of track since only a few wagons have to be drawn out at a time.

The first and foremost of these local installations is the sick yard (see inset), the place where wagons are brought in for repairs. On arrival in the reception yard, a train is first examined and wagons needing repairs are marked out. During sorting operations on the train, defective wagons are thrown on one or more lines in the sorting yard which are specially reserved for this purpose. Light repairs are carried out in the sorting yard itself, whereas wagons needing more extensive treatment are drawn out via the shunting neck and placed in the sick yard. As repair work in the carriage & wagon workshop may take some time, the usual procedure is to shunt these wagons to a platform known as the transhipment platform where hamals are employed to transfer the contents of defective wagons on one side of the platform to another set of wagons lined up on the other side. Following transhipment of goods, the newly loaded wagons are returned to the sorting yard whilst those which needed repairs, now empty, are shunted away to the workshop.

At break-of-gauge junctions a transhipment platform of another kind may also be found having tracks of different gauges alongside, this facility allowing goods arriving on one gauge to be transferred to wagons of the other gauge before they can resume their onward journey to their final destination.

Repacking wagons arriving on road van trains are laid out on a separate line in the sorting yard from where they are periodically drawn out and deposited at the repacking shed, an engine shunting them back into the sorting yard when repacking has been done. A weighbridge is also illustrated, the position indicated being suitable for occasional wagons that need weighing. However, at places where each wagon entering the yard needs to be weighed, a more suitable location for the weighbridge would be somewhere on the hump itself.

Wagon cuts deposited on sorting lines are generally separated by gaps of varying lengths. Once a train-load of wagons have accumulated on a line, the cuts are coupled, a guard's brake van added, and the train is shunted to the departure yard. For an up train (proceeding towards the right), an engine from the locoshed makes its way along the loco line entering the departure yard from the right hand end, attaches to the train, and draws out. An analogous procedure exists for a down departing train which is left as an exercise for the reader.

Those who are familiar with railway working will have noticed that the layout above doesn't show a goods shed. A goods shed is essentially a loading - unloading point : a place where consignments arriving by road transport are unloaded, booked, stored and finally loaded into railway wagons, facilities also being provided for the reverse process, namely, unloading of wagons and handing over the material to the consignee. The railway goods shed which serves this function is usually situated in the vicinity of the passenger station area. If you are wondering why there is no goods shed in the figure above, the reason is simply that the layout above is an example of a yard located a few miles away from the passenger station area. It is not unusual to find such a configuration : at Nagpur, for example, the marshalling yard is at Ajni which is a good 2 kilometers from the main station. Another example is the Itarsi New Yard.

When yard and railway station are remotely situated, a daily shuttle service is introduced between yard and shed. During hump-shunting, goods shed wagons (for the town in question) are collected on a line in the sorting yard, and at the appointed time, an engine picks up these wagons and proceeds towards the passenger station area, often without a brake van, to deposit them at the goods shed for unloading. Then picking up loaded wagons from the shed, it returns to the yard where the wagons are hump-sorted and placed on the appropriate lines in the sorting yard.

Multiple Yards

The single yard described above has all the essential features that will be found in a marshalling yard. On Indian Railways, though, the system, as noted earlier, has been to have separate installations for up and down directions. A multiple yard will consist of the following key elements : (1) Up reception, sorting and departure yards laid usually in continuation, (2) Down reception, sorting and departure yards laid alongside and parallel to the up yard, and pointing the other way, (3) separate humps for up and down yards, (4) connections between the two yards for the movement of cross-traffic and, (5) various auxiliary installations such as locoshed, sick yard, transhipment platform, repacking shed, weighbridge, goods shed, etc., each of these having suitable connections with the yard.

Marshalling yards can show an almost infinite variation in the way the constituent elements can be grouped together. Consider for example a case in which a yard is to be designed with limited funds in hand. If the traffic passing through the station is low the general procedure would be to adopt a flat yard design, combining the reception and departure yards into one unit. Below we find one such example. This flat yard has separate up and down yards, each made up of reception-cum-departure lines, and sorting lines which are dead end sidings. Once a train is formed in the sorting area it is carried to the reception-cum-departure yard where it awaits departure. In the example below, the yard is attached to the passenger station. The passenger platform area and station building are sandwiched between up and down yards, and can be reached by the foot overbridge. To keep things simple, we have omitted the repacking shed and transhipment platform, however it is worth noting that the goods shed is within the yard area, thus doing away with the need for a special shuttle service connecting yard and goods shed.

The Sorting Process

The hub of every marshalling yard is the classification yard where trains are broken up routewise. The number of lines here will depend, in general, on the amount of traffic handled by the yard. There may be as few as 5 or 6 lines, while at the other end, in a large yard where traffic is dense there may be as many as two dozen lines in the sorting yard.

The actual number of lines needed is worked out at the time when the yard is in the design stage. Each line is set aside for a certain purpose, and when the yard becomes operational every effort is made so that the nomination is not altered.

As an example, let us suppose that an analysis of traffic passing through a station is made and it is found that each day enough wagons arrive on incoming goods trains to form (a) one full train load for a certain destination A, and (b) two full train loads each day for another destination B. Then one line in the sorting yard will be reserved for destination A, and two lines for B. In an actual yard the nomination of lines could be something like this :

| Line No. 1 | Long distance wagons for destination A |

| Line 2 and 3 | Long distance wagons for destination B |

| Line 4 | Section train wagons for route 1 |

| Line 5 | Section train wagons for route 2 |

| Line 6, 7 and 8 | For sorting section train into geographical order |

| Line 9 | Repacking wagons |

| Line 10 | Goods shed wagons |

| Line 11 | Coal wagons for loco shed |

| Line 12 | Sick wagons needing light repairs |

| Line 13 | Sick wagons to be sent to sick yard |

| Line 14 | Guard's brake vans |

The table above should be regarded with caution for it can easily convey the feeling that a sorting yard needs at least a dozen lines in it. In practice, when traffic is low, two or more kinds of wagons are often allotted to a single line in the yard.

Sorting is a continuous process and may be compared to a man who's receiving a steady stream of coloured lollipops, and must pack them in boxes, red ones in red boxes and so on. He must pack each box to capacity before he can pass it on for delivery, and what is more, he must keep pace with the volley he is receiving. If more lollipops arrive than he can handle in a given time he'll find his room getting congested and must therefore halt the process so that he is able to clear out his room.

Bearing this analogy in mind we turn to the yard where we find that a section train has arrived in the reception area, awaiting sorting. A shunting engine attaches to the train from the rear and begins to push it up the hump. The Assistant Yard Master has full details of the train with him, and he has prepared his cut-list so that (a) section wagons for route 1 are sent to line 4, (b) section wagons for route 2 are sent to line 5, (c) any long distance wagons go to line 1, 2, or 3, as the case may be, (d) goods shed wagons are dispatched to line 10, (e) sick wagons, if any, are sent to 12 or 13 as the case demands (see table above), and (f) the guard's brake van rolls into line 14.

It is important to realize that all that this process has accomplished is to isolate section wagons route-wise : wagons for route 1 are all on one line, but they are still mixed up as far as stations along the route are concerned. When enough section wagons have accumulated on a line, the next thing to do is to arrange them in station-order. Making its way to the sorting yard the shunting engine picks up these wagons and draws back into the reception yard using a line which bypasses the hump, for a second round of hump shunting. Five or six (or even more) 'humping operations' may be required to juggle these wagons (using lines 6, 7 and 8) before they are all on one line in geographical order. This secondary sorting is usually done in the main classification yard itself but in some cases a separate yard is built for detailed classification work of this kind. This is known as a subsidiary yard.

In the meantime the shunting engine is running short of water, so it makes its way to a nearby line having an ash-pit, coal stack and water column. This arrangement can save a good deal of time as the shunting engine doesn't have to make its way to the loco shed every time it needs to be coaled or watered.

While all this is in progress a shuttle service has arrived from the station goods shed with 5 wagons for destination A, and 4 wagons for wayside stations along route 2. The shunting loco picks up the rake and in one humping operation deposits the first 5 wagons on line 1 (for destination A) and the rest on line 5.

Long distance trains consisting of loads for destinations A and B are dealt with in a manner similar to the procedure described above.

Coal wagons meant for the loco shed are reserved for line 11. On completion of its shift of duty, the shunting engine picks up these wagons and makes its way to the shed. As yard operation takes place round the clock, another engine at the shed takes over, picking up empty coal wagons from the shed and returns to the yard.

While the process of sorting forms the principal function of a yard, it is by no means the only object of concern. Each yard has to deal with a large number of empty wagons held in storage on lines close to the sorting yard. Empties are attached to section and van trains for clearing traffic booked at wayside stations. In addition, most yards are required to fulfill certain marshalling commitments such as supplying a fixed number of empties each day to a cement factory or colliery. Any shortage of wagons will mean that one or more train loads of empties will have to be ordered from a nearby division which has a surplus. While standing on an overbridge watching an empty goods train rumble by, it is good to bear in mind that the movement of empty wagons from one place to another is as much a vital link in the transportation of goods by rail as anything else.

As sorting work progresses in a yard, wagons begin to accumulate on various lines - long distance trains on the lines appointed, section trains, and so on. How long does it take to form a train? This depends in general on the way the wagons are distributed within the yard. A railway official I spoke to recently said that once a train has arrived you can never say with certainty when it will resume its onward run. Another factor that creeps in is the availability of sufficient load : are there enough wagons on a line to dispatch the train? A train may be dispatched underload, but this practice, if continued long enough, can prove to be uneconomical as we are not making full use of available engine power. Wagons bound for a certain direction may thus have to be left waiting in the sorting yard till such time as a sufficient quantity of load materializes.

Some Thoughts on Goods Loading and Unloading Points

The goods train of today is composed of BOX wagons, some closed, others open, each running on pivoted bogies and coupled together with center buffer couplers. Prior to the 1950s, BOX wagons were unknown ; most wagons were simple 4 - wheelers. There were specially designed wagons with appropriate ventilation for carrying livestock, other kinds for perishables, and oil tankers, all running on four wheels. If you were to move around in a yard you would most certainly discover that the railways have a tremendous job to perform, moving goods from one place to another.

Statistics indicate that about 60 -70 percent of the total earnings of the railways come from the movement of goods. Have you ever stopped to wonder where do all these loaded wagons originate, and how do they find their way into a marshalling yard?

Goods loading points can be broadly classified into the following 3 categories :

Railway Station Goods Sheds

The amount of traffic booked here will depend in general on the size of the station. At large stations and important junctions 10 - 15 wagons may be booked each day. On the other hand, at smaller stations along the way, the number could be 4 or 5, or even less, depending on conditions of trade.

At large stations which have a marshalling yard, wagons loaded at the station goods shed are taken to the yard, sorted and attached to various section and through trains, as we have seen earlier. At wayside stations the procedure is somewhat different. Wagons loaded here are picked up by a section train when it comes along, and conveyed to the next yard down the line where they are sorted and attached to various trains as appropriate.

Scattered Loading and Unloading Points Around a City

An industrialized area may have several production units and factories scattered around a city, each with its own siding together with connections leading to the main line. For loading and unloading, shuttle services (also known as pilots) are run connecting the marshalling yard with these units. Wagons containing raw material arrive by train and are laid aside on a marshalling yard siding from whence they are picked up and taken (together with any empties needed) to the industrial siding for unloading of material. The engine then picks up wagons loaded with finished goods and returns to the yard where the load is attached to various trains and dispatched onwards.

Large Industrial Sidings, Railway Goods Terminals, and Collieries

These are places distinguished by the fact that train loads of material are loaded and unloaded each day.

Let us take the case of a steel plant. Train loads of iron ore arriving in the nearest marshalling yard are taken to the plant and unloaded. The wagons, now empty, are loaded with finished steel goods and returned to the yard for onward dispatch.

Large sized railway goods terminals work in much the same way. Wadi Bunder railway goods shed, which is close to Bombay Victoria Terminus, is perhaps the finest example. This is no ordinary goods shed with a single platform and four wagons parked in a row. Wadi Bunder, in earlier days, had a total of 14 sheds for loading and unloading of commodities. The main yard that serves the Bombay area was at Kalyan where two lines converge : one coming from Igatpuri, the other from Poona. The function of Kalyan marshalling yard was to receive incoming trains, sort them out, and dispatch loads to (1) Wadi Bunder, (2) Bombay Port Trust Railway, and (3) send trains/pilots to unload goods at Byculla and other places lying to the south of Kalyan.

Each day something like 4 - 5 loaded trains were dispatched from Kalyan towards Wadi Bunder. As there is dense suburban traffic on the Bombay - Kalyan route during the day, these trains would have to be dispatched only during the night. Unloading would begin at Wadi Bunder during the early hours of the morning. Following this, the wagons were shunted into place for loading of goods, and train loads dispatched to Kalyan the following night where they were sorted and dispatched onwards.

While this is an oversimplification of what actually took place at Wadi Bunder, it does give the reader the feel of what goes on in a large railway goods shed where material is handled each day in train loads.

We have been laboring over a seemingly unimportant issue here, trying to discover the source at which goods items actually originate. But this exercise, though apparently pointless, is meant as a drill for the beginner who is finding himself muddled and who wishes to have his concepts cleared. The first thing that emerges is that a marshalling yard is by no means a place where goods are loaded or unloaded. Loading is always done at a railway goods shed, industrial siding, colliery, oil refinery, a food godown, or some such place. The principle is the same almost everywhere : wagons loaded at one or more of these places are carried to a marshalling yard, sorted out and attached to various loads (section and through trains, etc.) depending on the destination booked for.

Secondly, when a train is formed in a yard for the purpose of dispatch, it is said to start from the yard. After it has travelled a certain distance and pulls into a yard where it is broken up, it is said to terminate at this yard. Termination therefore occurs at a place where the train is split up, some parts resuming their onward journey on other trains, while some will make their way to a goods shed or siding for unloading of material.

David St. John Thomas, a noted authority on railways, said in one of his books that most goods trains begin and end their careers in a marshalling yard. The reader who has followed the reasoning so far will have no trouble in seeing what John Thomas means.

Yard Operation

At the heart of a marshalling yard organization is the Yard Master having a number of Assistant Yard Masters under him working in 8 hour shifts. At multiple yards dealing with heavy traffic, separate Assistant Yard Masters are assigned to up and down yards. AYMs need to be fully conversant with the yard layout, the procedures to be followed, and the general programme followed each day: a yard could easily turn into a hopeless mess were it not for these men who hold charge of all that takes place which includes sorting, formation and dispatch of trains together with all the necessary planning done in consultation with the Control Office.

Shunting work is performed by Shunting Masters working under the direction of the AYM on duty. Each such shunting master is in charge of a shunting engine and is assisted by 3 - 4 pointsmen allotted to hump sorting and other related work. Besides this, there's other staff to take care of various auxiliary functions : the Train Examiner and his men, repacking shed foremen, transhipment clerks, carriage & wagon repair staff, cabinmen, call boys, brake (or skid) porters, and others.

The staff above comprises the executive side of the yard organization. Together with the executive staff, the Yard Master has another organization under him known as the Trains Branch, made up of a Head Trains Clerk, one or more Assistant Head Trains Clerks and several Trains Clerks. The trains branch is solely concerned with statistical work which involves daily stock taking of wagons, entering wagon particulars in yard registers, and preparing marshalling yard statistics.

Let us try to follow the sequence of events when a goods train (or a shuttle) has arrived in the reception yard. The first thing to do is to send the engine to the shed. Loco sheds are protected by a cabin which control both entry and exit; the AYM therefore phones the CASM of this cabin informing him of the arrival of the train. The CASM in turn phones the loco foreman and on getting permission, he will set the points and lower the signals for the engine to return to the shed. In the meantime, the Guard has made his way to the AYM's office where he hands over the wagon way bill before signing off duty.

Trains are generally sorted in the order in which they arrive, and it may be several hours before the load will be backed up on the hump for shunting. Meanwhile, there are other important things to do, such as number taking and train examination.

If you are standing in the reception yard, you will find a man slowly moving along the length of the train taking down particulars from wagon labels in a handbook he is carrying. This is the trains clerk (or number taker as he is known), and he is noting down details of each wagon - wagon number and type, owning railway, starting point and destination, tare and gross weight, and whether loaded or empty. He will also record the load of the train and net tonnage (e.g., 60/2000) together with the position of wagons carrying livestock or perishables, if any. Following the process of number taking the load is subjected to an intensive examination by the train examiner and his staff. A memo issued by the TXR tells the Assistant Yard Master which of the wagons were found sick so that they may be placed on the appropriate lines in the sorting yard during humping operations on the train.

In the meantime, the TNC will have handed over his record to the trains branch where wagon particulars will be entered in various yard registers maintained in the office.

Yard and Control

As a through train moves from starting point to destination it often calls on intermediate yards, halting only briefly for engine watering and C & W examination. At these yards, therefore, only a limited number of trains are broken up, and the main activity revolves around passing through trains. On the other hand, there are yards whose geographical position will mean that nearly every train that arrives has to be broken up and new trains formed.

Bhusaval, which was a multiple yard with separate up and down humpyards, makes an interesting case for study. This can be seen in the map appearing in Figure 6, which shows the areas for which trains were formed by Bhusaval UP yard.

Like every other yard, Bhusaval UP yard developed a certain fixed pattern of traffic over the years. Thus, each day the yard would receive terminating through trains containing a mixture of loads, sort them out, and form through trains for the following destinations: (1) Wadi Bunder, (2) Bombay Port Trust Railway, (3) South of Kalyan, (4) Raichur, (5) via Hotgi, and (6) beyond Sabarmati, etc. Lines were therefore allotted in the sorting yard for each of these destinations.

A word of explanation is in order here. A term such as South of Kalyan means wagons meant for various goods sheds and industrial sidings in the Bombay area. In a similar way, via Hotgi is used to denote loads bound for stations beyond Hotgi: these will travel together as a through train right up to Hotgi where they are sorted out and dispatched onwards.

Since the destinations and vias for which trains are formed constitute a fixed pattern, it will be helpful if the yard maintains particulars showing the total number of wagons it has in each group. Thus for example, Bhusaval Up Yard, at a certain time, may contain a total of:

- 120 wagons for Wadi Bunder (WB load)

- 60 wagons for Bombay Port Trust Railway (BPT)

- 75 wagons for South of Kalyan (SOK)

- 45 wagons for via Hotgi

- 75 wagons for Raichur

- 20 section wagons for Manmad - Dhond

- 130 wagons for beyond Sabarmati

- ------------------------------------

- 125 empty wagons

- 8 wagons for Bhusaval goods shed

- 3 wagons for Bhusaval repacking shed

- 4 coal wagons for Bhusaval loco shed

- 5 sick wagons

- 7 goods brake vans

Tabulated data of this kind showing the current yard composition is available in a register maintained in the yard known as the Running Balance Register. Each time a train arrives in the yard, a TNC goes out and takes down wagon details which are counted up and added to the appropriate columns of the register. In much the same way, when a train is about to leave the yard, wagons details are noted by a TNC which will be counted and figures subtracted from the columns.

The current yard composition is relayed to the Control Office at 4 hourly intervals or more often as required. Control requires this data for the following three reasons: (1) to study the loads lying in the yard and see if there is sufficient load for a certain train, (2) to check and see if there is a sufficient stock of empties in the yard, and (3) to keep a constant watch on the total yard balance ; this figure is important, for if it goes beyond the working capacity of the yard, congestion sets in and work comes to a standstill.

Control, with its ever watchful eye, acts as the nerve centre that coordinates the activities of various yards within the division. Each day in the morning, the control office prepares a table known as the Divisional Wagon Balance. This is an extensive table prepared with the help of particulars collected from various stations and yards during the night. The divisional wagon balance is usually recorded on a blackboard in the control office and shows the number of wagons in different marshalling groups (e.g., Wadi Bunder wagons, Raichur load, empty wagons, etc.) for each of the yards and line sections of the division. An example of a divisional wagon balance table, in shortened form, can be seen below:

The divisional wagon balance tells us at a glance what is the position with respect to different wagons groups both on trains which are running on various sections, as well as those in yards within the division. This information is vitally important for it enables the officials in charge to see what is taking place all over the division and plan out things accordingly. The balance will tell for instance whether there is a sufficient number of empty wagons at a break-of-gauge transhipment point, and in case of a shortage, from where empties could be ordered. More importantly, the divisional wagon balance enables the officials in charge to work out a tentative schedule for the whole of the day: the trains to be run over the division, their composition, what time they are expected to arrive at various yards, and so on.

Turning now to the yard, we find that number - taking is done both for trains as they arrive in the yard and those that are ready for departure. Besides this, a line-to-line position is also taken at the beginning of each shift of duty and relayed to control.

On reporting for duty, the first thing an AYM does is to study the line position which tells him about the trains in the reception yard, the loads lying in the sorting yard, and trains awaiting dispatch in the departure area. To take an example, Bhusaval UP yard could have a line position at a certain time as depicted below:

It is clear that each line in the reception yard holds a full length train: line number 2, for example, has a load consisting of 10 wagons for Bombay Port Trust Railway (all together, of course) and 50 wagons for Raichur, together with the goods brake van. The line position is meant to assist the AYM in assessing what he has in hand and plan out things accordingly. He must also get in touch with control over the phone to discuss which trains are likely to arrive during his shift of work, what loads can be formed in the sorting area, and so on.

The idea underlying planning is a simple one and its purpose is to decide how best to recombine the wagons lying in the reception area with those in the sorting yard so as to (1) form through trains to the farthest possible destination , and (2) dispatch loads lying in the yard with the least amount of detention.

An example should make this clear. Each day, Bhusaval UP yard forms a through train for each of WB, BPT, South of Kalyan, via Hotgi, and Raichur (see line position and map above). It also dispatches a train-load of wagons for the Manmad-Dhond section ; these travel as a through train to Manmad where they are sorted and dispatched onwards as a section train headed towards Dhond.

Today, however, it turns out that owing to a slump in trade, only 15 Manmad-Dhond wagons have materialized at Bhusaval. When control sees that there is no prospect for more wagons in this direction, it is likely to advise the Bhusaval AYM to attach these 15 wagons on line 6 of the sorting yard to the Wadi Bunder load on line 1 and dispatch it as a through train to Manmad (see map above). Once the train reaches Manmad, these 15 wagons are detached and what fate awaits them will now depend on the circumstances. But at least they have reached Manmad, and this is better than to lie idle, perhaps for several weeks, in the Bhusaval up sorting yard.

Local Traffic in a Yard

About 40% of the total number of wagons in a yard turn out to be local wagons, or home loads as they are known. These are wagons for which the yard serves as a terminal, and include coal laden wagons for the loco shed, goods shed wagons, repacking wagons, and sick wagons. Experience shows that home loads show a tendency of increasing to alarming proportions unless they are dealt with promptly, so in most yards a programme is drawn up to expedite work. This would mean, for instance, that when a new batch of staff report for work in the morning, the first thing to do is shunt sick wagons which have accumulated in the sorting yard to the sick yard. Similarly, at a preset time repacking wagons would have to be taken to the repacking shed, and brought back after the repacking foreman has issued a memo certifying that his work is accomplished. Even goods shed wagons are picked up from the sorting yard according to the programme laid down.

Drawing up a programme is a fine thing ; keeping to the schedule is another matter and requires sustained effort. An AYM of a large yard is likely to find that it is almost impossible to deal with local wagons according to the guidelines laid down. He then has to do the next best thing, and that is to see that posting of local traffic is not postponed indefinitely, for a yard is essentially a place where traffic flows, and wagons left stagnating in one place, if not dealt with on time, will sooner or later lead to trouble at some other spot.

Ordering a Goods Train

An assistant yard master has four main functions to perform:

(a) Receive incoming trains without detention. For this, he must expedite sorting work so that room is made in the reception yard to receive an incoming train.

(b) Form trains according to the 'marshalling orders' of the yard in consultation with control.

(c) Dispatch trains, again in accordance with instructions laid down by control.

(d) Deal with local wagons, as far as possible according to the programme laid down by the yard.

On reporting for work, an AYM will find a certain number of trains awaiting departure in his yard. These were formed during the previous shift of work. The loads which our AYM will form during his shift will be shunted away to the departure yard and will be dispatched by the AYM who next turns up for work. How does our AYM decide what time a train is to be dispatched?

It works something like this. Once a train is formed in the sorting yard, the cuts are coupled up, a brake is added and the load is hauled into the departure yard. Control is informed that a load has been formed to a certain destination, and having done this, the AYM can take his hands off the matter and turn his attention to other things.

Control now turns to the important task of fixing a suitable time for departure. This is a matter that will be influenced by two main considerations. To begin with, the Power Controller who is in constant touch with loco sheds in his area, has to check and see when an engine is available. Secondly, a goods train has to be dispatched during the interval between two consecutive passenger trains, and certain 'gaps' can be highly undesirable. For express through trains, controllers generally select a gap that will give a clear run of several miles before the train is held up on the way for precedence. The progress that a train will make when dispatched at a certain time is often worked out graphically and is known as a 'path'. Each day several such paths are worked out in advance. 'Very good paths', giving a clear run of several miles are reserved for express through trains, whereas 'normal' paths are meant for ordinary through trains. There are paths for section and van trains, as well as 'uneconomic' paths where a train would make very poor progress, and are to be used only in emergencies.

Having decided on a suitable time, control now issues a 'train notice' to the yard and shed. The process is known as 'ordering a train' and consists of issuing written (or more often telephonic) advice to the yard and locoshed stating the time at which the load is to be dispatched. A train notice will say for instance that : "Raichur load will leave as C-30 (i.e., at 3-30 hours) ; book driver and guard to work on C-30 with Engine number." Details of the notice are taken down by the loco foreman, as well as by the trains clerk in the yard in a register known as the train notice register. Together with the departure time and date the notice also specifies the engine number : clearly then, the notice could be issued only after control has finalized matters with the loco foreman concerning the engine that is to work the train.

In earlier days, no train could ever leave the yard without being ordered in the manner described above. Even a goods shuttle had to be ordered by control before it could make its way from yard to goods shed. Section trains were generally ordered to leave sometime near about midnight, while Road Van trains were ordered during the day. A goods shed shuttle would be ordered during the night.

A train notice is generally issued 3 - 4 hours prior to the departure of the train. This generous space is allowed so that the following things may be done:

(i) The AYM's office books a guard to work on the train. In booking a guard (as well as a driver) the criterion followed is that the person who was the first to return after completing a stretch of duty will be booked out first, provided he has received at least 12 hours rest. A call boy makes his way to the guard's home with a call-book some 3 hours before departure, so that the guard may be able to report for duty well in time and sign-on in the duty register.

(ii) The loco shed books a driver who has to report at the driver's lobby in the shed about an hour and a half before the engine leaves the shed.

(iii) A TNC goes out and takes down wagon details in his handbook - these will be used to update the Running Balance Register, and also to prepare the Wagon Way Bill to be given to the guard of the outgoing train.

(iv) The AYM issues a memo to the train examiner (TXR) asking him to examine the train. This is again an elaborate examination taking nearly an hour or two during which everything from wheels and brake-blocks to couplings and vacuum connections are checked. The men will also check up open wagons to see if any of the loads have shifted due to rough shunting, whether wagons doors are properly closed, seals are intact, and so on.

Once the engine is 'on the load' it is customary for the driver and guard to walk along the length of the train to see if everything is in order. The driver also checks the vacuum on the train and when he is satisfied with the reading on the gauge, both he and the guard sign a vacuum certificate furnished by the TXR. Carbon copies of this certificate are given both to the driver and the guard, while the original remains in possession with the Train Examiner.

Armed with the vacuum certificate, the TXR is now in a position to inform the assistant yard master that the train is ready to run. On receipt of this message, the AYM phones the end cabin asking the CASM in charge to take line clear from the station ahead. Once line clear is granted, the cabin sets the points and signals and the goods train is ready to move out.

Mechanised Yards

A mechanised yard is a term used to describe a humpyard that has been upgraded by the addition of appropriate electrical and electro-pneumatic control devices so as to speed up the rate of sorting of a train. Mechanisation can thus be looked upon as a refinement that allows more trains to be sorted in a given period than would be possible in a yard of conventional design.

The principal features of a mechanised yard are as follows:

(i) A hump with a height ranging anywhere from 10 to 20 feet (it was 11 feet 6 inches at Mughalsarai). Increasing the height of the hump means that wagons will roll down towards the sorting yard at faster speed.

(ii) A weigh-rail a little beyond the apex of the hump with coil springs and pressure transducers below which give a visual indication to the control cabin of the weight of the wagons passing over the hump.

(iii) A set of retarders to slow down wagon cuts rolling down the hump. A retarder is an electro-pneumatic device operated from the control cabin and consists of two pairs of horizontal brake beams at track level, one pair for each rail. When operated, beams of each pair draw closer gripping the wheels of a passing wagon at their lower extremity in a nutcracker fashion, thereby slowing down the movement of the vehicle.

(iv) The points are set electro-pneumatically. Switches on a panel in the control cabin allow routes to be set individually for each successive shunt as it comes rolling along. Alternatively, a perforated tape is prepared which when fed into a machine, sets the routes automatically without the need for intervention from the operator.

The first yard in India to be upgraded was Mughalsarai UP yard which was mechanized in May 1962. In a mechanised yard, wagons are not uncoupled as they go over the hump. Instead, the train is split up while it is still in the reception yard. Following the process of train examination, a shunting jamadar walks along the length of the train, uncoupling wagons as he goes along and enters details (e.g., first two wagons go to line 7, etc.) in a tally. This is checked by the office and a tele-typed copy sent to the control cabin which prepares a perforated tape for automatic route setting for successive shunts.

Two WG class engines were used at Mughalsarai to push the train continuously up the hump. The speed was around 3-4 kmph, which meant that a 60 vehicle train could be broken up in about 10-12 minutes thus making it possible to sort about 40 trains each day. As wagons pass over the weigh-rail, bulbs light up in the control cabin giving the following indications:

| X (extra light) | up to 9 tons |

| L (light) | 9 - 15 tons |

| M (medium) | 15 - 24 tons |

| H (heavy) | Over 24 tons |

These indications are for the operator so that he can decide on the extent of application of the retarder. The correct use of the retarder, however, is a job that requires some skill as the amount of braking needed will also depend on the distance the shunt has to move before coming to halt on a sorting line. Despite the use of retarders, wagon shunts acquired speeds of around 25 kmph in rolling down the hump : skids were therefore employed additionally to prevent violent collisions.

Finally, each sorting line has axle counters fitted which give an indication of the space left on the line in terms of number of wagons, the figure changing with each vehicle that is deposited on the line.

A Peek at Mughalsarai

"If you are interested in it now," said Dale Carnegie, "it is because you have learned a new and strange fact about it." This brief treatise on marshalling yards is meant to do just that : to fire the reader's imagination and arouse in him a new sense of enthusiasm for the multitudinous activities that took place in a goods yard. If you are one of those who are beginning to find the adrenaline rushing at the mere sight of a goods train winding its way out of a station, here's something that will send your pulse racing still further. You have been waiting for ages to see what it was like, and now it's there for you to browse and study at will, to move around amongst the labyrinth of lines and turnouts, and marvel at the piece of wizardry devised by those grand old men of the railways.

Have a good day exploring Mughalsarai yard !

Some Other Yards

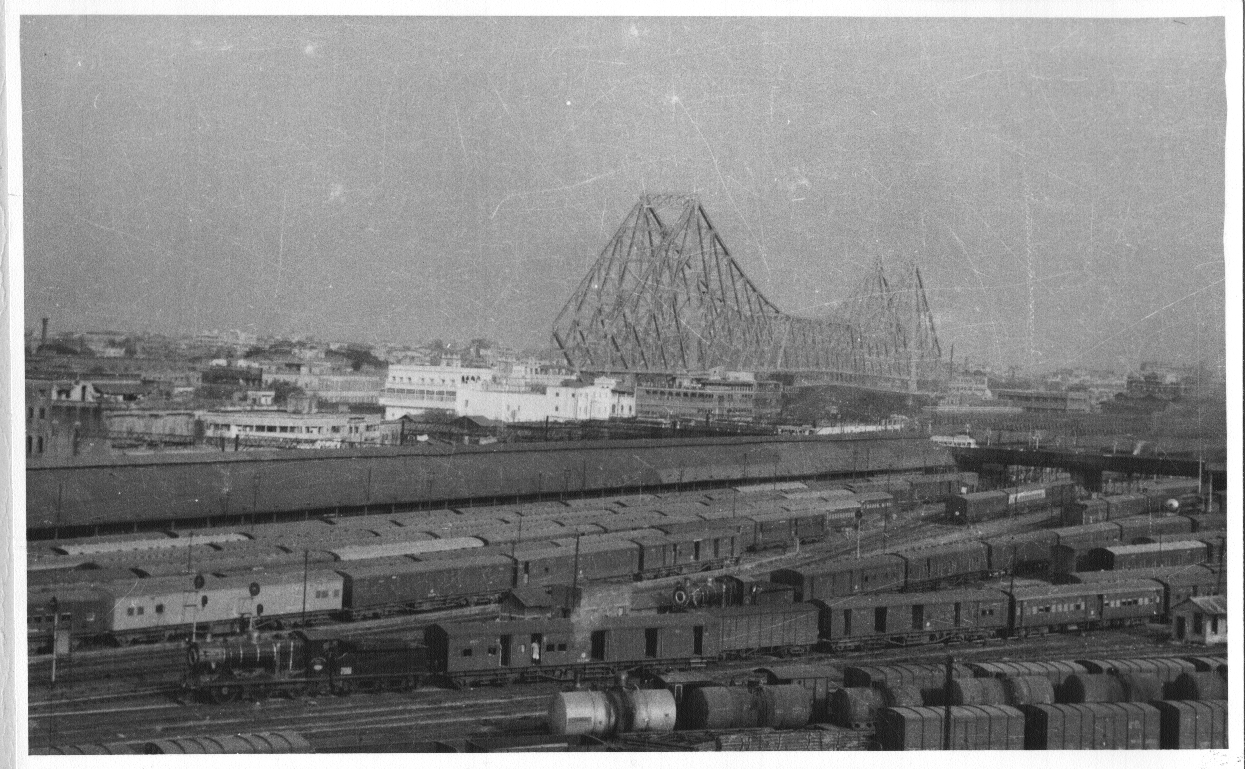

A few scanned photographs of Howrah and Mughalsarai yards in years past, provided by Harsh Vardhan.

Material provided by Ravindra Bhalerao, Copyright © 2008. Howrah and Mughalsarai yard photographs provided by Harsh Vardhan.